Turning big ideas into great products

We are a world-class team of designers and industrial engineers.

If it can be imagined, it can be made

From startups to Fortune 500s, we design product solutions for the world's best brands.

We help make your vision tangible

We build the bridge between the world of ideas and the delivery of products.

Of CNC Machining

CNC Machine Experts

ISO 9001:2015

We work on the forefront of innovation and technology to take products from an idea all the way to the end consumer.

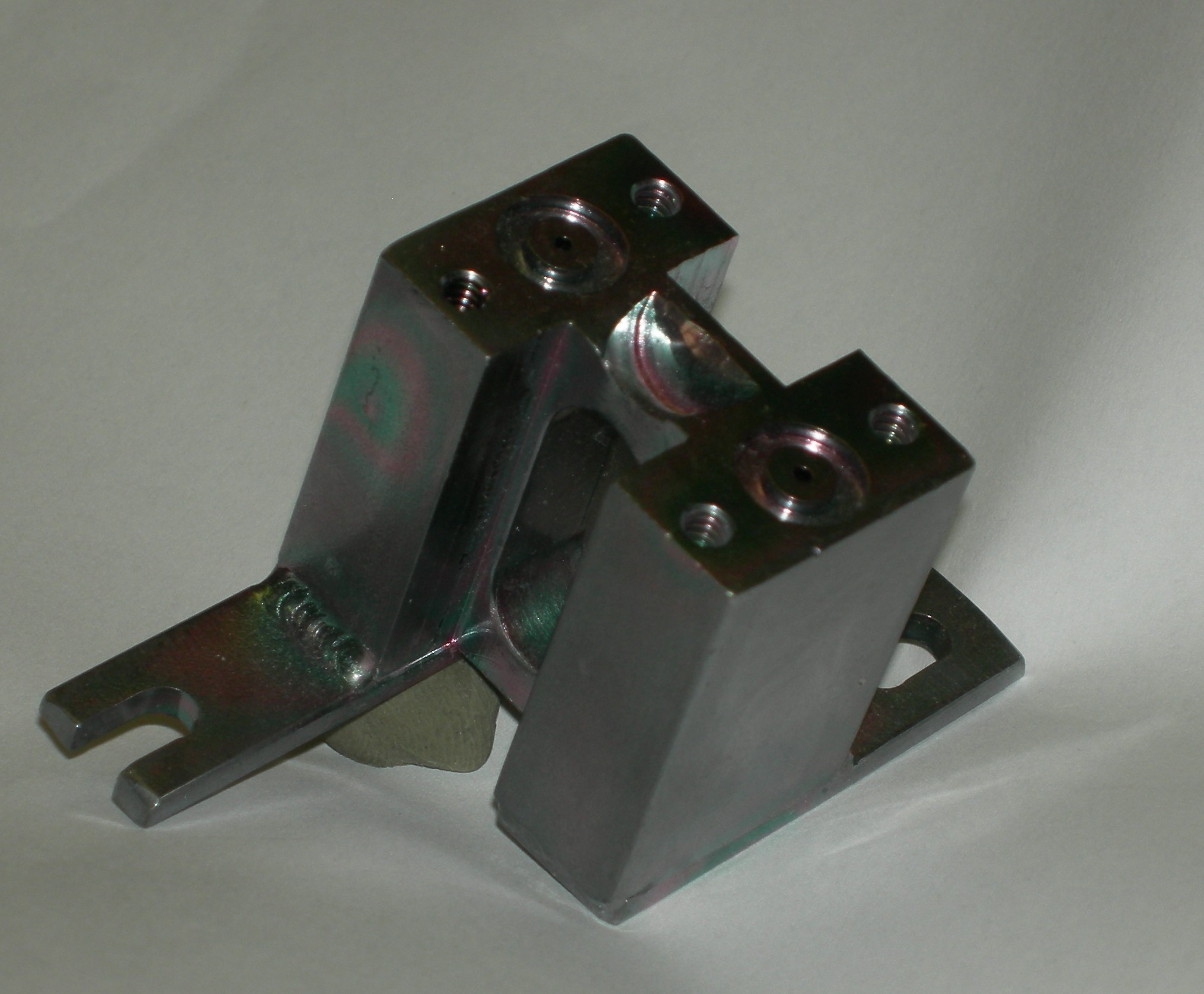

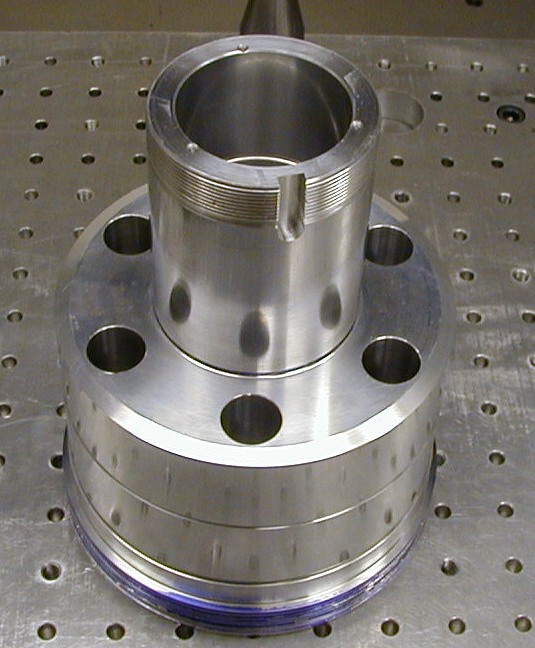

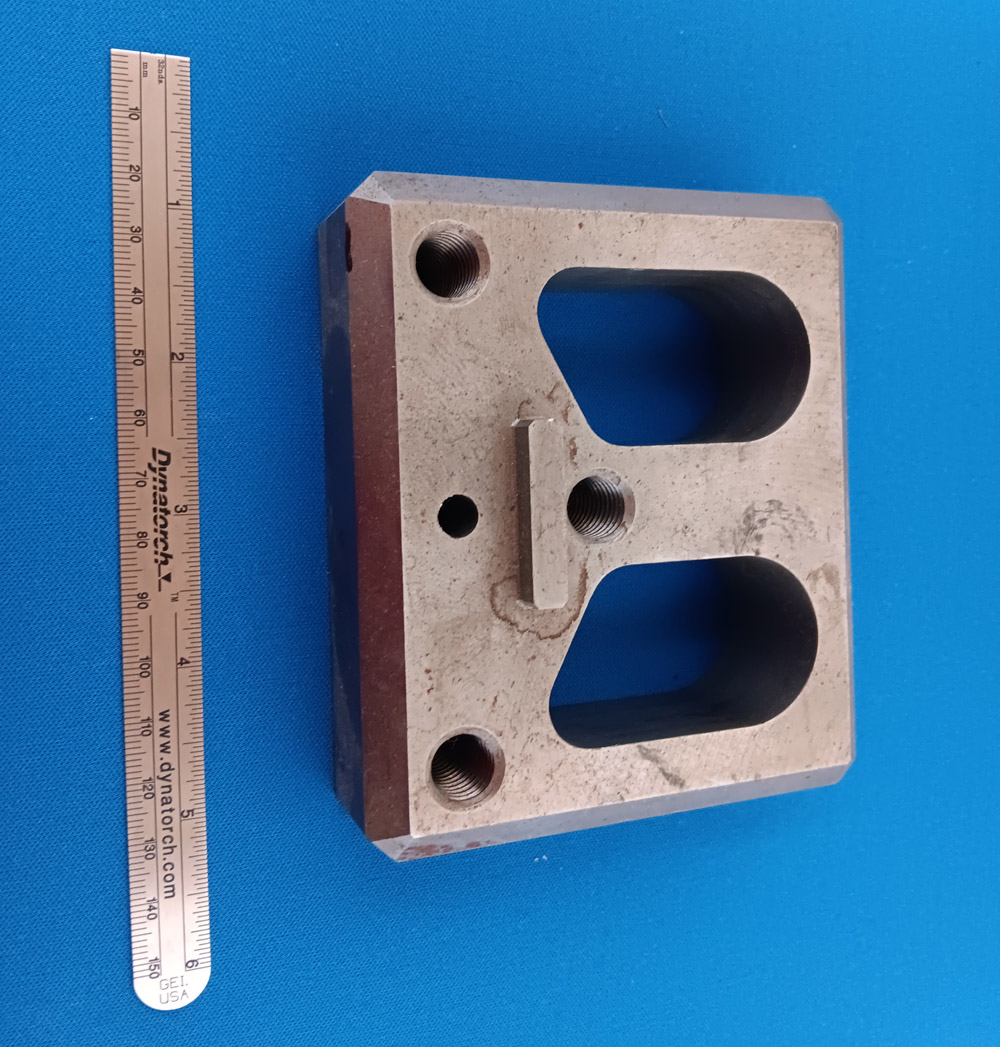

Our high-speed precision CNC Milling environment is designed to produce the highest quality output possible. Our processes can be used to deliver a multitude of precision parts for use in any environment.

Our CNC Turning Department is in a constant state of change! We are constantly seeking ways to improve our setup and run times. One way to do this is to utilize the storage capabilities on our CNC Turning equipment.

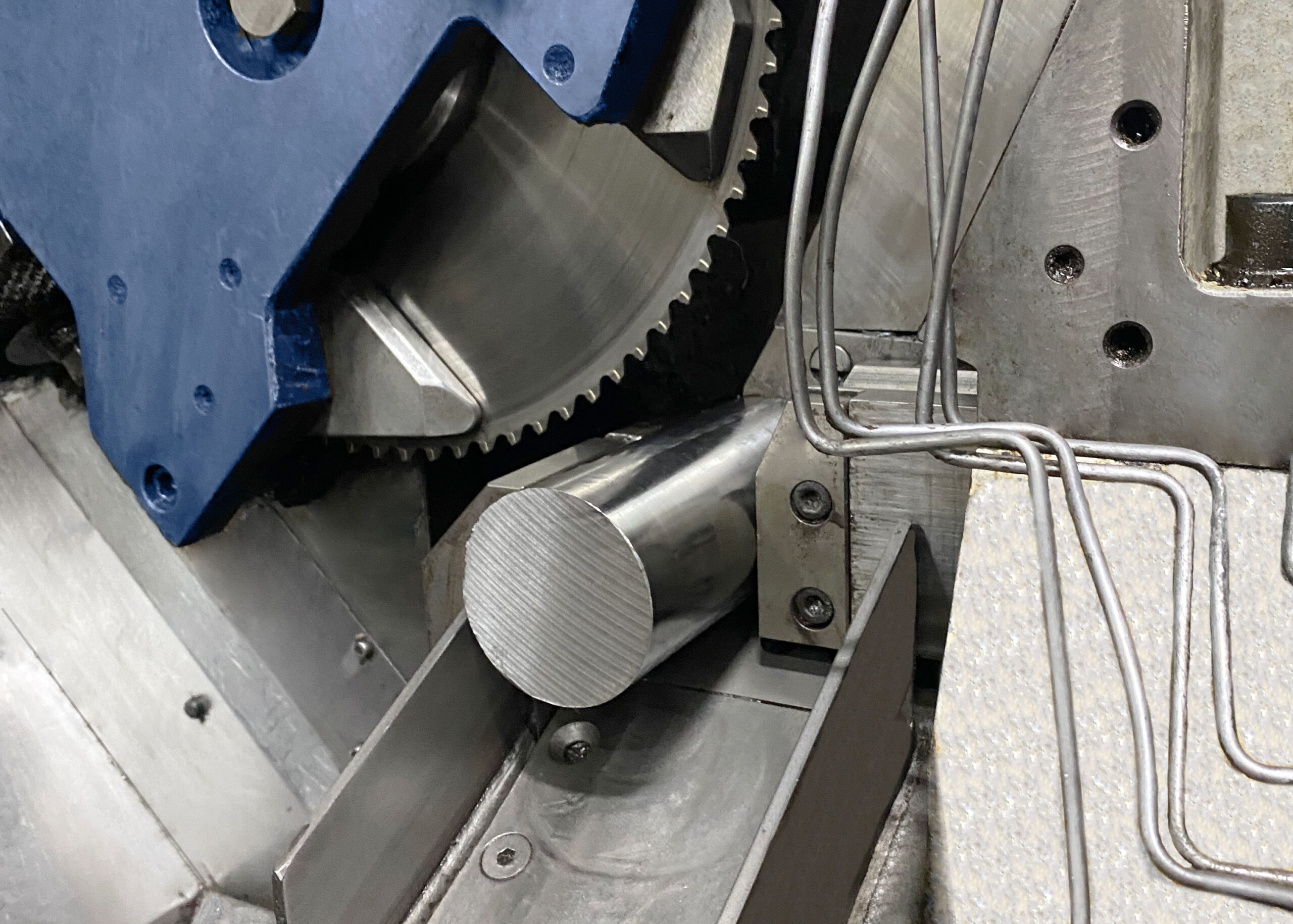

With the purchase of the Hyd-Mech Band Saw, we cut our sawing time by 50%; and, because of the precision cutting we have reduced the milling and turning time required to complete a part.

At Frecon, we are able to handle your Tube, Rod and Flat Metal Bending projects. Our experienced team, utilizing advanced equipment, can make tight radius bends in various materials to your exacting specifications.

If you want a finish that is cost efficient, chip and crack resistant, flexible, does not fade, has no EPA regulations because it contains no solvents, and it extends the life of your part from damage caused by moisture and chemicals – then Powder Coating is what you need.

We offer CNC Lathe Services precision machining for complex parts and components. From prototypes to production runs, we deliver accurate and efficient turning solutions

Our Swiss Turn services provide high-precision turning for complex parts and components, ideal for tight tolerances and intricate designs

We provide expert CNC machining solutions to businesses. With over 35 years of experience we’ll ensure that you’re always getting the best results from an award-winning team focused on quality.

Frecon Company began in 1960 with the invention of the “Bug Stopper” – a simple product created at a kitchen table. Now over 50 years later, Frecon INC offers a full range of CNC machining services, including welding, milling, turning, cutting, bending, powder coating and assembly. Our mission to be your dependable and trustworthy manufacturing partner and supplier.

Your innovative thinking coupled with our capabilities create a powerful environment for innovation! Let our experienced team of professionals at Frecon INC help turn your idea into reality!

Want to get in touch? We'd love to hear from you. Here's how you can reach us.

513-874-8981